Which industries is the CNC milling edge machine suitable for processing in?

As a high - precision and high - efficiency processing equipment, the CNC milling edge machine has a wide range of application fields. Specifically, the CNC milling edge machine is mainly suitable for processing in the following industries:

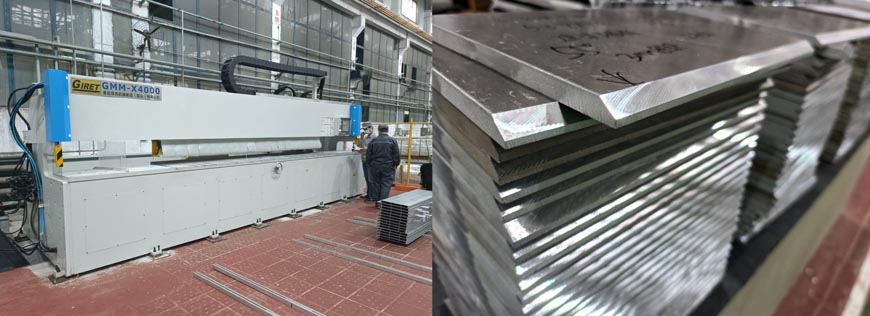

CNC edge milling machine、CNC beveling machine、Batch beveling processing effect of steel plates

Shipbuilding Industry: The hull of a ship is welded from a large number of steel plates and steel pipes. The CNC milling edge machine can be used to process the grooves of these steel plates and steel pipes, ensuring the strength and tightness of the ship's structure. For example, when processing the groove of a marine propeller shaft tube, it can guarantee the firmness of the shaft tube installation and welding.

Petrochemical Industry: In the construction and maintenance of oil and gas transmission pipelines, the CNC milling edge machine is used for groove processing of pipelines to ensure pipeline welding quality and prevent oil and gas leakage.

Construction Steel Structure Industry: In the production of construction steel structures such as the steel structure frames of high - rise buildings and the roof truss structures of large - scale stadiums, it can process the grooves of a large number of steel profiles and steel plates, improving the welding quality of steel structures and ensuring the overall stability of the building.

Aerospace Industry: It can be used for fine - processing the edges of high - precision parts such as aircraft engine parts, aircraft structural parts, and spacecraft structural parts, meeting the stringent technological requirements of the aerospace field.

Automotive Manufacturing Industry: It can be used to process automotive engine parts, automotive chassis parts, automotive body parts, etc. For example, milling the edges of metal sheets of the automotive chassis in preparation for subsequent assembly and welding.

Power Industry: It is used to process various metal components in power generation equipment, such as edge processing of components like the stator and rotor of a generator, ensuring the connection and assembly accuracy of components and guaranteeing the stable operation of the power generation equipment.

Construction Machinery Manufacturing Industry: For various metal structural parts in construction machinery, such as the boom of an excavator and the bucket of a loader, the CNC milling edge machine can process their edges, improving the strength and reliability of the structural parts.

Boiler and Pressure Vessel Manufacturing Industry: The manufacturing of boilers and pressure vessels requires high precision in steel plate processing. The CNC milling edge machine can perform high - precision processing on the edges of steel plates, ensuring the welding quality and pressure - bearing performance of the vessels.

Teaching and Training Field: In welding teaching at technical schools, for example, the VF1500 CNC milling edge machine can enable students to conduct high - precision groove processing practices, helping students master high - quality welding techniques and understand the welding characteristics and processing requirements of different materials.

In conclusion, with its high - precision and high - efficiency processing capabilities, the CNC milling edge machine plays an important role in multiple industries.