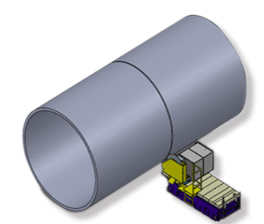

PIpe Circumferential Seam Milling Machine introductions:

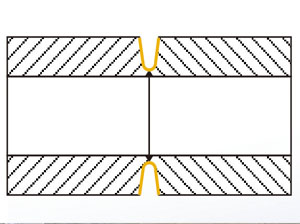

The product adopts a heavy - duty formed cutter head cutting method. It is a device used for beveling the circular weld between two pipes after the inner bevel welding of the circular weld joint of the two pipes, and for back - gouging the welded inner - wall weld seam. It can be adjusted according to the change of the circular weld position. It is mainly used for external beveling operations in the manufacture of pressure vessels and large - diameter pipes.

PIpe Circumferential Seam Milling Machine Technical Parameters:

Power supply voltage: AC380V/AC415V/AC220V 50HZ/60HZ

Total power: ~100KW

Floor area: L4500*W1900mm

Equipment height: 2200mm

Processing speed: 0 - 2000mm/min

Processing pipe diameter: φ1500 - 10000mm

Processing pipe wall thickness: 6 - 100mm

Bevel type: U/J+V bevel

Bevel angle: 16°

Operation mode: HMI (Human - Machine Interaction)

Touch - screen size: 15"

Processing materials: AL (Aluminum), SS (Stainless Steel), Carbon (Carbon Steel)

Product Features of Pipe Circular Weld Beveling Machine/HuFeng Beveling Machine/Circular Weld Edge Milling Machine

Note: Pipe Circumferential Seam Milling Machine, Circular seam milling machine, pipe CIRC seam milling machine