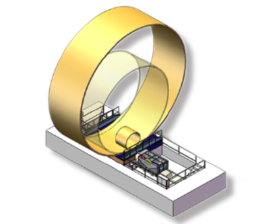

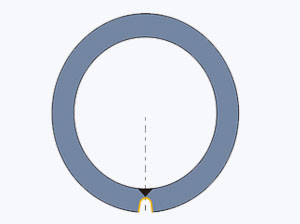

The product employs a heavy - duty formed cutter head for cutting, and the effective processing length can be customized according to users' needs. After the inner - bevel welding of pipe rolling, this product is used to perform root - gouging operations on the longitudinal weld bevels and internal welds of the pipes. It is mainly used for longitudinal weld beveling in the manufacturing of pressure vessels and large - scale pipelines.

Main Technical Parameters of Pipe Longitudinal Weld Root Cleaning Machine / Pipe Longitudinal Weld Beveling Machine

Power supply voltage: AC380V 50HZ

Total power: ~120KW

Floor area: L14500*W5450mm

Effective length: 1.5/2/3/4/6m

Cutting speed: 0 - 3000mm/min

Processable pipe diameter: φ1000 - 10000mm

Processable pipe wall thickness: 6 - 100mm

Processable pipe length: ≥1500mm

Bevel angle: 16°

Bevel type: U/J+V

bevel

Operation mode: HMI (Human - Machine Interaction)

Touch - screen size: 15 inches

Main characteristics of the Pipe Longitudinal Weld Root - cleaning Machine / Pipe Longitudinal Weld Bevelling Machine

Note:Long Seam Milling Machine, longitudinal seam milling machine, Pipe longitudinal seam milling machine